Partner:

News

Schiess - Pressemitteilungen

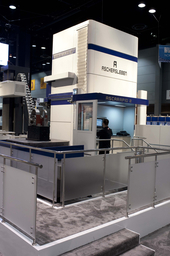

Short delivery times with medium-sized machining centers

With a focus on the modular ASCA series, Schiess is geared towards low-volume production

The machine tool specialist Schiess is currently positioning itself in the international market with medium-sized centers for 5-sided machining. The product range consists of the ASCAMILL table-design portal milling machines and the ASCARAPID boring machine series and supplements the long-established portfolio of high-quality vertical turning machines and portal milling machines in table and gantry designs. A multi-axis vertical turning machine and a large horizontal turning machine are currently under development and are due for presentation towards the end of 2013 or in 2014. The ASCA machine centers are designed for use in automotive and energy systems engineering, in mechanical engineering and tool making and in contract production.

These precision machines are notable for their cost-effective configuration and short delivery times. "The ASCA series is based on a modular system. By using standardized assemblies, we can supply our customers quickly with high-quality, individual manufacturing solutions," explains Marc Springstein, Head of Sales at Schiess Tech GmbH.

Accurate and smooth running

With full cast frame modules and a load-optimized arrangement of drive systems and guides, ASCA machining centers operate accurately and very smoothly. Automatic tool changing with chain or multilevel magazines and loading during primary processing time ensure optimum and very economical use of the production facility.

The ASCARAPID boring tool machines workpieces for the energy and the mechanical engineering sectors. These include pump, valve and transmission housings and chassis and frames for machines and vehicles. Servomotor-driven x, y, z and w axes and transmissions and spindles with double nuts combine high rigidity with maximum precision. Oil-air lubrication is provided for the hollow spindle bearings. The machine is therefore particularly suitable for very high spindle speeds (e.g. spindle diameter 160 mm: 3,200 rpm). A pre-tensioned spherical bearing ensures that the rotary axis remains rigid allowing very tall workpieces to be machined with no shortfall in performance.

Easy access, fast tool changes

The ASCAMILL machines precision parts on which large areas need to be accurately milled out or which need to be drilled accurately to within a few hundredths of a millimeter. These include railroad trucks of any size, components for tunnel drilling machines and also molds and frames for industrial production equipment. The milling portal is very flexible with a table 2, 2.5 or 3 meters wide and 4 - 10 meters long which can take loads of up to 40,000 kg. The axes of the ASCAMILL are equipped with an absolute measurement system and make time-consuming reference runs to the starting point superfluous.

Highly operator-friendly

All the machining centers are controlled with a Siemens 840D sl system (safety integrated) or with a Fanuc or Heidenhain system. The self-explanatory screens on the console make it easy to operate the machine. Schiess uses the condition monitoring software Autinity to plan maintenance and remote servicing. Users of the system can link directly to the Schiess service center via the Internet.

Design award for the housing

Last year, the system housing received the internationally renowned "red dot award: product design 2012" in the Industry and Crafts category. The products are characterized by sleek forms with rounded edges. The rows of windows in the housing allow inspection of the systems and at the same time give them visual depth. As a result, it is easy to maintain an overview of the systems and quickly determine how they are functioning. The design of the machines therefore helps to reduce the work involved in operating them.

Schiess Tech GmbH (www.schiess.eu)

Schiess applies its expertise and 150 years of experience to designing and manufacturing reliable machine tools for the international mechanical engineering sector. As well as the new ASCA series of medium-sized machining centers, the company develops and builds large-scale plants used to machine components for windmills, turbines or assemblies for the shipbuilding industry, to name just a few examples. Since 2004, Schiess has been part of Shenyang Machine Tool Group (SYMG) China.

Contact information:

Schiess Tech GmbH, Marc Springstein, Head of Sales, Tel.: +49 (0) 69 4305328-34,

E-mail: m.springstein(at)schiess.eu

Schiess Tech GmbH, Mónica Ramos Martín, Marketing, Tel.: +49 (0) 69 4305328-33,

E-mail: m.ramos(at)schiess.eu

Media Contor, Heinrich Junghanns, Tel.: +49 (0) 40 300696-20, E-mail: junghanns(at)mediacontor.de

ASCARAPID 1-5 boring machine series for 5-sided machining of workpieces in the energy and mechanical engineering sectors. These include pump, valve and transmission housings, and framework and chassis for machines and rail vehicles.

ASCA machining centers: Easy operation with consoles showing self-explanatory screens.

The ASCAMILL machines precision parts on which large areas need to be accurately milled out or which need to be drilled accurately to within a few hundredths of a mil-limeter.